High-speed Automatic SMT Mounter

· 6 YAMAHA high-precision SMT production lines

· Chip placement accuracy:0201

· FPC/Hardboard mounting

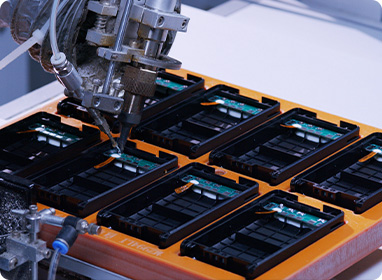

Automatic PCB Testing Equipment

· Automatic PCM function testing and data storage

· PCM MES comprehensive data traceability system

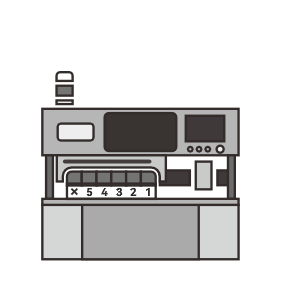

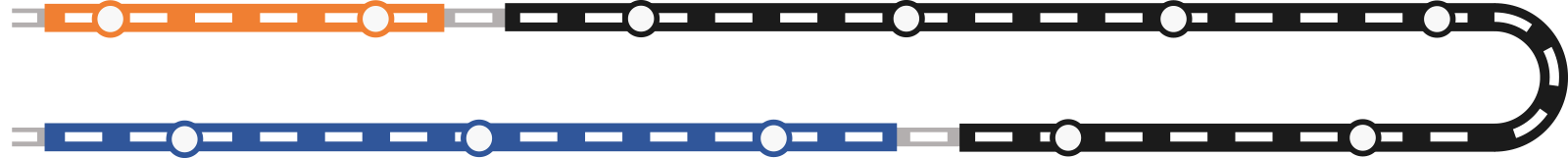

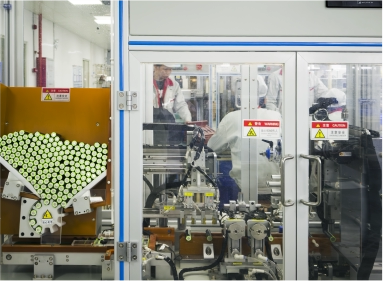

Automatic Cell Matching Equipment

· Sorting cell voltage, consistency in internal resistance

· Enhancing battery module performance

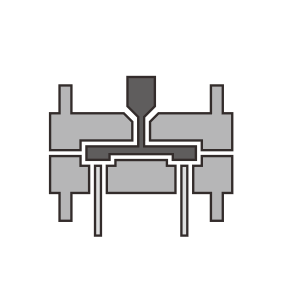

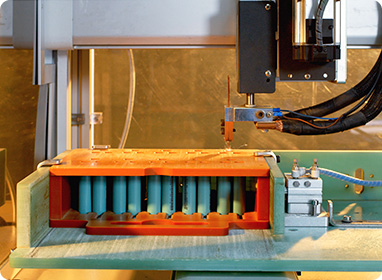

Automatic Dispensing Machine

· Automatic and precise adhesive application, dispensing

· Enhancing efficiency and reliability

Low-temp. Injection Molding Equipment

· Ensuring the quality of plastic molding

· Enhancing the structural strength of Lipo battery module

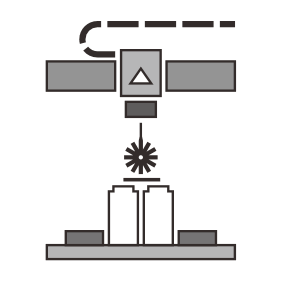

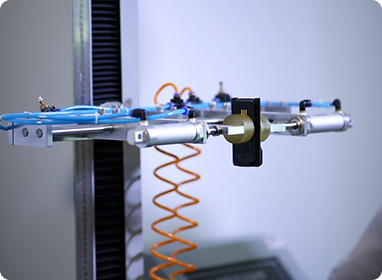

Laser Spot Welding Equipment

• High precision, automation

• Improving product reliability and consistency

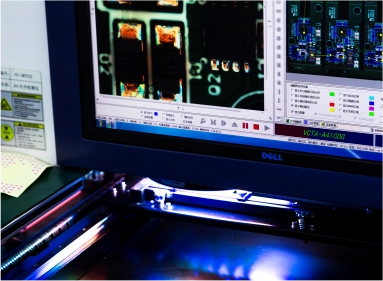

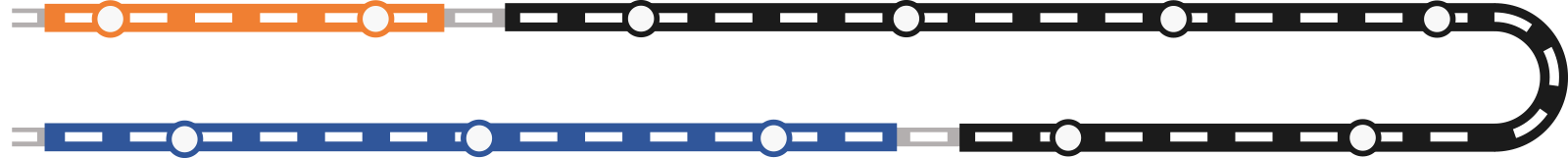

1 PCBA Manufacturing / Functional Testing

2 Production and Assembly

3 Finished Product Inspection

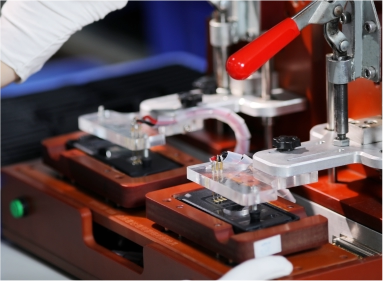

Automatic Soldering

Equipment

• High precision, automation

• Precise positioning of spot welding locations

• Ensuring welding reliability and consistency

Laser

Engraver

• Automatic engraving of battery labels, QR codes

• Battery MES comprehensive traceability system

Waterproof Testing

Equipment

• 100% automation for IP67/IP68 water-proof testing

• Visualizing data for precise assessment of water-proof performance

• Guaranteeing product safety and reliability

Code Reading Test Equipment

• Automated programming for mass production

CCD Device

• Automated verificationof label content correctness and repetition